1

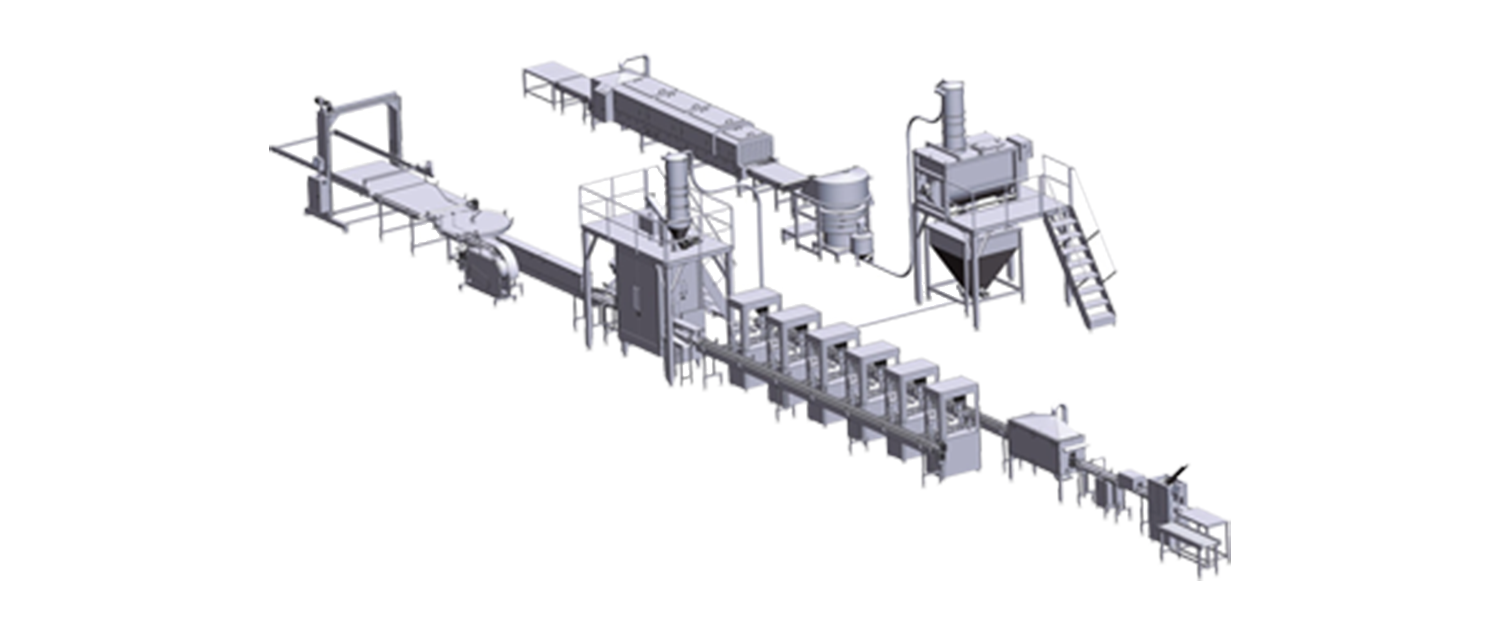

Depalletizers are machines that unloading empty cans from stacks and push them to next step like canning turntables automatically.

2

Canning turntables makes the cans in a line,then the cans will enter the Can Cleaner.

The cleaner contains many UV lamps and a vacuum cleaner, which can eliminate microorganisms, bacteria, and viruses and remove the dust that may come with the can.

3

The worker remove the outer packaging of semi-finished products and just the inner packaging left.

4

The bags that have been unpacked are sent into a clean tunnel,which machine likes can cleaner,also includes many UV lamps and a vacuum cleaner.

The tunnel can eliminate microorganisms, bacteria, and viruses and remove the dust that may come with the inner bag.

5

The worker remove the inner bag,and put the powder into the Feeding Station.This feeding station contains a screen that can screen powder,then the powder is ready to Convey to Mixer.

6

7

The step is convey the powder after mixing to the filling for filling.

We produce some kinds of Conveyor,such as Dense Phase,Vacuum and Screw conveyor.

8

Filling Powder,this is the core function of the production line.

We produce many kinds of Filling machine,such as single filling head,multipil filling head,for can or for bag,even for big bag,in this line,the filling machine is for can.

9

The step the can or bottle need to be seal by Sealing machine.

Sometimes the air in the can is pumped out and then injected with nitrogen, which is finally sealed to extend the shelf life of your product.

10

Clean the can after sealing is necessary.This will ensure automatic operation of the entire line.

11

Labeling and Capping will be customized according to your needs

Products

Contact Us

POWPK

M 1502-1503, NO.61, NANJING ROAD( E) SHANGHAI 200002, CHINA

WhatsApp/WeChat/Tel.

086 18117071017

Mo-Fr: 8:00-19:00

Sa-Su: 8:00-14:00