The influence of the number of factory floors on the design of powder production lines

Preface

The design of the powder production line plays a crucial role in the success or failure of the entire project. A good design needs to consider the following factors:

- Output;

- Cost;

- Occupied area

- Maintenance costs.

And how to utilize the conditions of the existing factory building to optimize the design of the production line is a problem that we powder equipment manufacturers need to carefully consider.The existing additions to the factory include the number of floors, floor height, floor area, and floor load.Here, we will only analyze the impact of the number of floors on the design of the powder production line.

Due to powder conveying issues, the number of floors available in the factory greatly affects our design philosophy for the production line. Our design principle is to use the least equipment and occupy the least factory area to complete the entire production line.

Here are several typical production line designs

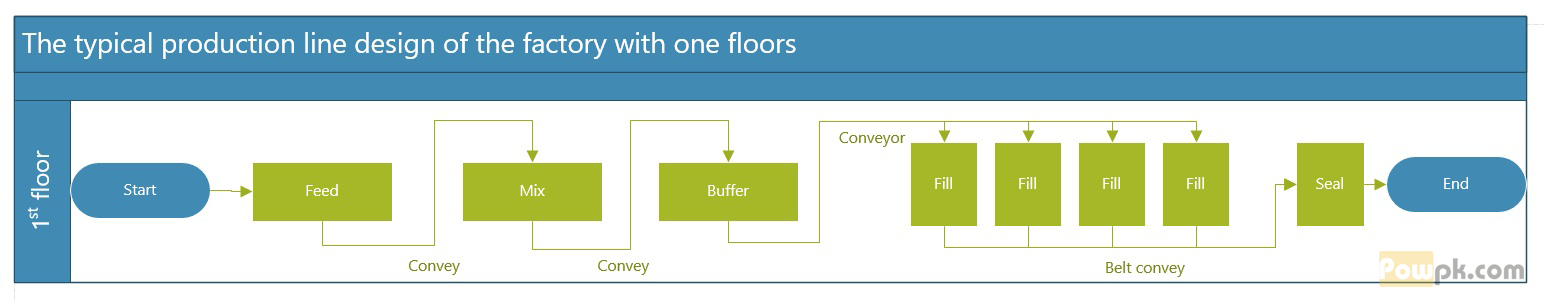

Only one floor of factory building(Horizontal layout)

In this design,the feeding station,mixer,filling machines and sealing machines are all put ont same floor.They all need to be connected by conveyor equipment.

A factory building with only one floor requires the most conveying equipment to allow materials to flow between the equipment. This type of factory has the largest floor area, the largest number of equipment used, the most difficult maintenance, and the highest cost. Moreover, due to the speed limit of material conveying equipment, it may have a significant impact on the production line’s output.

Two floor of factory building(Horizontal+vertical layout)

We put feeding station and mixer on the 2nd floor,the filling machine and the sealing machine on the 1st floor.

The design of a two-story factory building can use gravity feeding instead of conveying some materials, but due to the limited number of floors, conveying equipment is still required to transport materials. Compared to the design of a one-story factory building, this type of conveying equipment has been reduced. Due to the use of space on the second floor, the floor area is also relatively reduced, resulting in a certain decrease in production line costs.

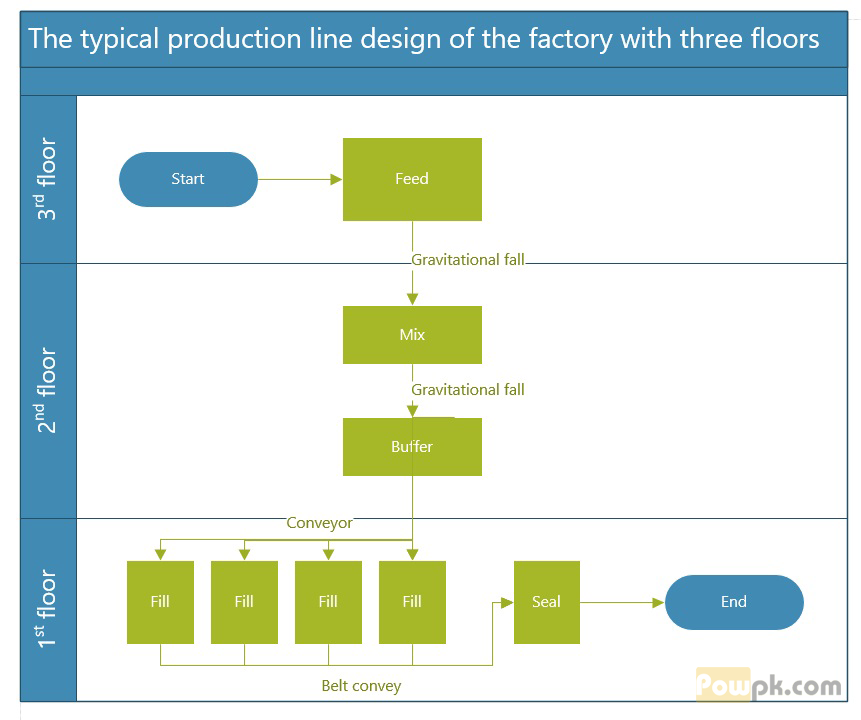

Three floor of factory building((vertical layout)

The feeding station is located on the 3rd floor,the raw material can be reached by elevator.The material falls into mixer on the 2nd floor by gravity ,After mixing,it falls into filling buffer silo by gravity again.Filling machine and sealing machines are still in 1st floor.

This type of factory building is the best structure, where the transportation of materials is completely replaced by gravity, resulting in the lowest cost of the entire production line and minimizing the impact of material transportation time on the production line’s output. Additionally, due to the relatively minimal procurement of equipment, the cost is the lowest.